Profit & Savings

Precision grinding of electrodes is a smart investment that pays off in both savings and efficiency. By ensuring a correct tip geometry through precise grinding, you optimize welding performance and stability. This not only reduces the need for frequent regrinds but also extends the lifespan of the Tungsten electrode.

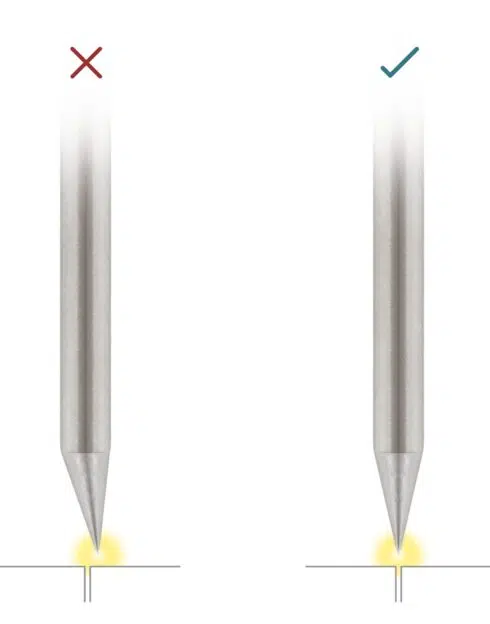

Precise grinding

A well-maintained electrode with a smooth surface minimizes material waste, as it enhances the electrode’s longevity and performance. In the long run, the upfront effort of precision grinding translates into cost savings, less frequent replacements of electrodes, and a more sustainable welding process.